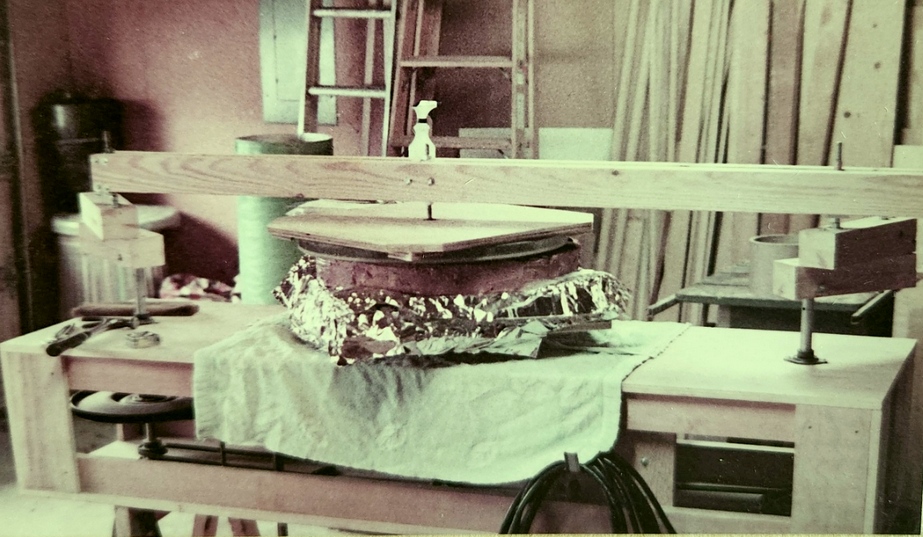

I designed and built a grinding machine for mirrors up to 42 inches [1.1m] in diameter. By slipping on and off a couple of belts, the machine can quickly be reconfigured for spinning work or for stroking work. The machine can also work smaller mirrors if the drip pan is moved to the fast shaft on the side of the machine.

For my first machine, a Draper design, go here.

I shared a Sketchup model if you want to see construction details.

Here's a short video showing the machine in action.

Some images followed by technical notes and links.

The motor is a 0.5 horsepower motor with 50:1 reduction = 1725 rpm / 50 = 34.5 rpm output.

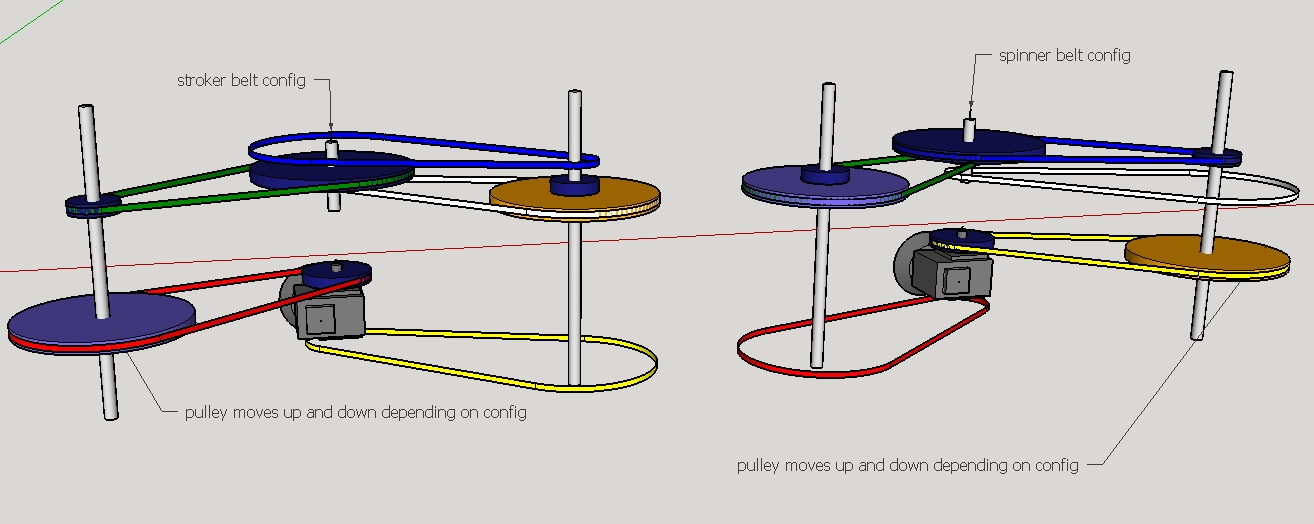

Belt and pulley arrangements for both stroking and spinning:

Reductions:

2.3:1 from 6 inch:14 inch

12.25:1 from 4 inch:14 inch + 4 inch:14 inch

Hindle/Zeiss mode:

main stroke = 34.5 rpm / 2.3 = 15 strokes/min

platter rotates at 15 rpm / 12.25 = 1.22 rpm

Elgin-Waineo mode:

platter rotates at 34.5 rpm / 2.3 = 15 rpm

side swing strokes at 15 rpm / 12.25 = 1.22 strokes/min

Small table Elgin-Waineo mode:

platter rotates at 34.5 rpm / 2.3 = 15 rpm

offset oscillates at 15 rpm / 12.25 = 1.22 rpm

Axes separation:

42 inch mirror with 21 inch radius, 80% stroke length = 17 inch stroke; 21 inch+17 inch=38 inch axes separation

motor to shaft and shaft to reducer set to 45 deg angle between axes or 27.25 inch

Pulleys:

V-Belt pulleys

6.25 inch dia, 6 inch 4L dia

14.16 inch dia, 14 inch 4L dia

4.75 inch dia, 4 inch 4L dia

Belt lengths:

V-belt 4L

motor gear reducer + 6 inch pulley to 14 inch pulley: 76 inch (qty=2)

14 inch pulley to idler of 4+14 inch pulleys to 14 inch pulley: 73 inch (qty=3)

Motor dimensions:

Face Mount Four 3/8 inch-16 tapped holes on 5-7/8 inch diameter B.C.

Base Mount Four slots on 5 inch x 3 inch centers

Shaft 5/8 inch dia. x 1-7/8 inch w/3/16 inch keyway

Size 8-1/2 inch x 7 inch x 8 inch

Gear reducer dimensions:

see pdf

Paint:

brilliant star yellow

Analysis:

Hindle/Zeiss style

25 inch stroke polishing should move no faster than one stroke every 4 seconds, or 15 rpm

need 34.5/15 = 2.3:1

rotating platter further 12:1 reduction

Elgin-Waineo

42 inch spinning should rotate at 20 rpm (20 inch mirrors at 40rpm, stroke at 5rpm)

need 34.5/20 = 1.7:1

stroke can be further 8:1 slower

compromise at 2:1, 12:1

2:1 from 6 inch:14 inch (2.3:1)

12:1 from 4 inch:14 inch + 4 inch:14 inch (12.25:1)

Belt lengths:

http://www.pyramidbelts.com/calc_beltlength.php

7/8 inch :motor gear reducer to 1 inch diameter primary shaft distance = 22 inch

pulley diameters of 6 inch and 14 inch

belt length = 76 inch

1 inch diameter primary shaft to reduction shaft 1 inch diameter to secondary shaft 1 inch diameter distances = 22 inch

pulley diameters of 4 inch and 14 inch

belt length = 73 inch

Cost:

$1800 (completed 2015)

1/2 horsepower AC motor, 50:1 gear reducer

belts, shafts, pulleys

MOM parts list

mirror machine examples with moving graphics, machine figuring action

mirror o matic images

Jeff Baldwin's machine

I ground (3) 20 inchers, a 24 inch, a 25 inch and a 30 inch with this machine.

eod