...by Tom Waineo

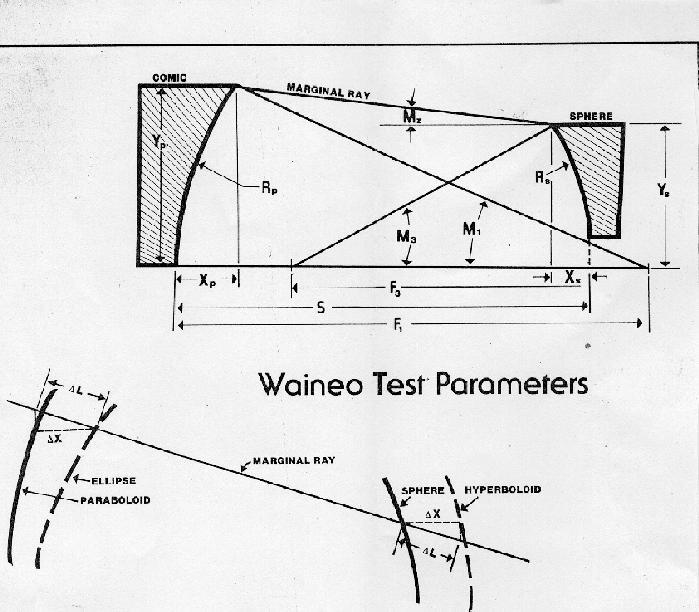

The Foucault knife edge test is a null test for a spherical mirror

at radius. Any error visible is a defect in the wavefront being

tested. A null means zero or nothing to measure. It is possible to

produce a quality spherical mirror which can be used in turn to null

a paraboloid. As before a visible error is a defect in the paraboloid

surface and thus the wavefront undergoing the knife edge test. Since

both mirrors are used at foci whereby they have spherical aberration,

a null is produced when those sphericals cancel. The author has used

the test for more than 25 years and presented in a article in

Telescope Making #11 and followed by Ed Jones in the July 1992 issue

of Sky & Telescope. What is now being presented is a update of my

experience in using the test.

The size of the sphere has a

affect on the sensitivity of the null. A small sphere requires a

shorter radius and a greater focal reduction to achieve a null than a

larger sphere. The best results is with a sphere of at least 1/2 the

paraboloid in size and a radius of 10 to 12 diameters. The test is

unique since the light source and knife edge are seperated, but on

the test axis. The source to sphere distance is always less then half

the sphere radius. The distance from the paraboloid to knife edge

falls between the radius and focal length. The seperation of the

mirrors is less than this distance so that the knife edge is behind

the hole in the sphere to make the test possible. When a F/5 sphere

is tested at radius, the test cone has a diameter/radius ratio of 10.

A null test of a F/5 paraboloid can be made at focus using a flat to

return the projected light back to the paraboloid for a return to

focus. The sensitivity of the knife edge test varies inveresly with

the square of the focal or radius ratio. A F/5 has 1/4 that of a

R/10, but because of the double pass, it is twice the 1/4 or now 1/2.

The same sensitivity can be obtained by testing at F/7.07 which when

squared is 1/2 of the R/10 squared. Such a null can be made by using

a sphere of at least 1/2 of the paraboloid diameter. Needless to say

that it is easier to make the sphere than a full sized flat for the

same test sensitivity.

The test for a 16 inch F/5 uses a 9

inch diameter centered on the 12 1/2 inch sphere of 116 5/8 inch

radius. Ed Jones program was used to design the null test and

confirmed by a ray tracing program. The light source, spherical

mirror and knife are are mounted together on a adjustable stand. The

light source distance to the spheriucal mirror and the knife edge set

at the distance behind the mirror. A tape measure is accurate enough

to set those distances. Since a sphere has no optical axis, it must

be set square to the line of source and the center of the sphere. By

placing a eye behind the light source, adjust the source so that the

center of the sphere, the light reflection by the sphere and the

source falls in a line regardless of how the eye is placed. This is

also done with the source turned 180 degrees to face the mirror.

Adjustment is done by viewing behind the hole and aim at the mirror

center with the test stand unit. Then the mirror stand is adjusted so

the center, source, and source reflection all are on a straight line.

Now return the source to face the sphere and if all is done

accurately, a return from the paraboloid now passes thru the hole. It

may look complicated, but once done, the procedure is easily followed

and further set ups is done in a few minutes.

If all is set as

per null design parameters, then the knife edge is at the focus point

of the null. If it is not, move the whole source, sphere, and knife

stand unit until the cut off is at the focal point. The seperation of

the two mirrors is the least critical of the design parameters. If a

shadow starts from the center and moves to the edge or begins at both

edges and advances to the center, than there is coma present. If so

double check the alignment. Note the blockage of light caused by the

source support. the first is the light passing between the mirrors

and the second is after reflection by the paraboloid on route to the

knife edge. The two shadows need to be combined into one. The cut off

should be uniform. If errors are seen, the slopes are evaluated as if

testing a sphere at radius.

The null can help to test a large

low focal ratio mirror when the Foucault sampling of points across a

diameter has two sources of error. One is the tester's ability to

make precise measurements. The second is the number of zones measured

could not accurately give a wavefront error profile. The null gives a

infinite number of points to assure profile smoothness. Even when a

perfect null is obtained, it only means that the slope errors are so

small that the eye could not detect variations of shadows and lights.

Since there is nothing measurable, it assures smoothness of whatever

wavefront error is undetected. There is no need to null a 6 inch F/8

for the Foucault test at radius is accurate. For a 10 inch F/5 or

larger mirrors, it is nice knowing that a null is available if you

ever need it for quality assurance.

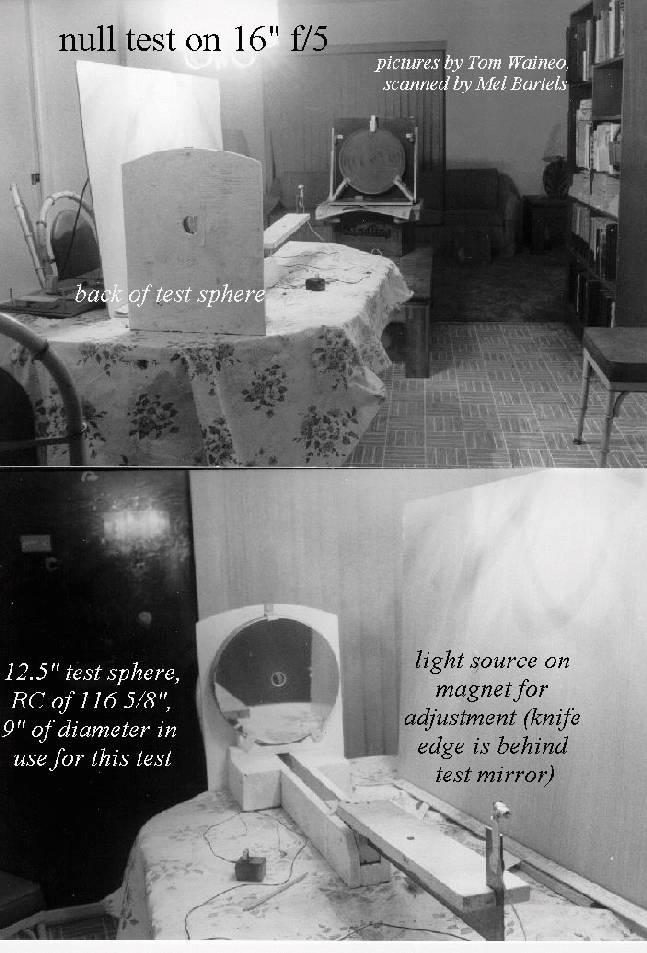

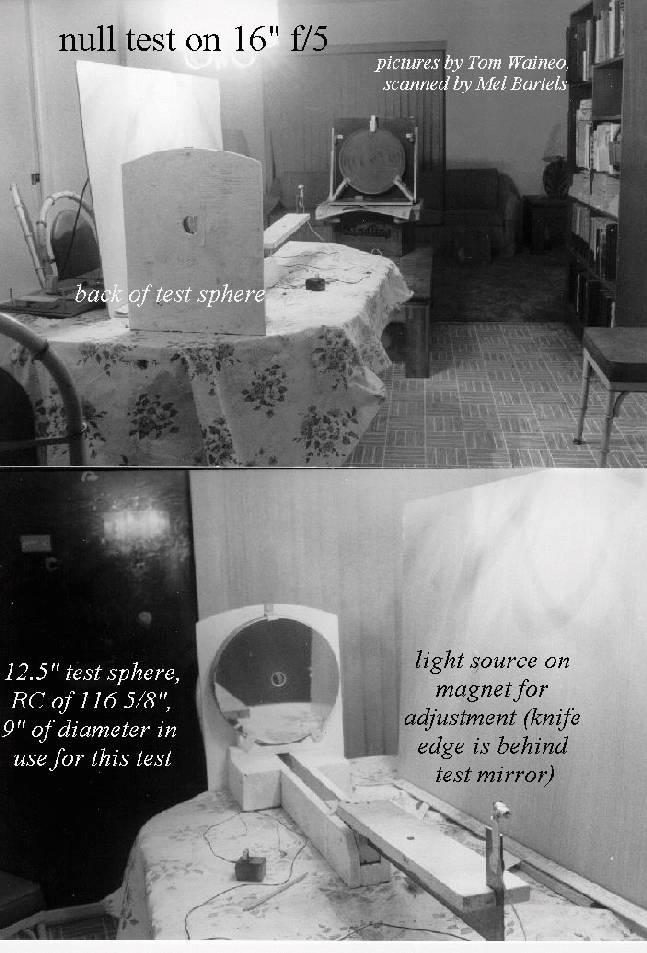

The enclosed images show a

16" f/5 being tested by a 12.5" sphere (9" of which is

in use).

more notes by Tom W:

I have been using this

null for 25 years. In the shops, there are many spheres used for the

Hindle test of Cassegrain secondaries and for Ritchey Common testing

of flats. With those mirrors avilable, they could be used to test

conics. I have 4 spheres of my own. A 5 of 51 radius, a 8 of 127

rad,a 12.5 of 116 rad, and a 11.5 of 29.5 rad that can be used for

testing. I have two projects now. One is to convert the optics of a

Celestron Comet Catacher Schmidt Newtonian of 5.5 F/3.6 into a Wright

Newtonian. The other is a 17 inch F/7.5 Ritchey Chretien Cassegrain

with a F/2.8 primary. The Hindle sphere was used to test the

secondary and would be used to null the primary as well. I found that

the Cass will null a source at 100 ft with a increase of back focal

distance and mirror spacing. The 100 ft distance uses the full

aperture of the secondary whereas for the infinite focus, the

secondary is oversized and the edge could not be seen for testing.

The 100 ft distance test means I do not need to borrow a big flat and

I can use a PDI (Point Diffraction Interferometer). I bought a $40

bar code He Ne laser from H&R. This laser is the smallest I have

ever seen. It is only a inch diameter and 6 inch long for 1/2 mw. A

12 volt DC power supply that plugs in the wall powers it.