Running for more than 20 years, the Oregon Star Party Telescope Walkabout celebrates and promotes telescope making. As a group we walk from telescope to telescope, meeting each builder, listening to their story. What is it about? What works? What doesn't? What would they change next time? Sometimes it is a novel idea, sometimes it is a beginner's first effort. We ask questions as a group, benefiting collectively. The popularity of the walkabout over the years shows its value to amateurs. Ask yourself if you'd rather be answering judges questions or talking about your telescope to an appreciative crowd. Awards and prizes create hierarchies where none exist, hide knowledge and cause people to act poorly.

The Oregon Star Party has seen the invention and early adoption of flex rockers, string telescopes, Tensegrity tube structures, wire spiders, computerized drive systems, direct drive motors, TrackBalls, SudiBalls, ultra-lights, three large one meter reflectors, super fast sub-F3 reflectors, folding light path reflectors, travel and folding scopes, 3-axis mounts, novel observing accessories, meniscus mirrors, ultra-thin mirrors, Lurie-Houghtons and Schiefspieglers, a number of binoscopes, club scopes and tracking platforms. Especially we take time to celebrate 'first' telescopes made by kids and adults. Invariably there is a fresh take, a new approach or a novel idea.

The Walkabout is the largest event outside of the star party's concluding door-prize event. This year's theme is innovation with telescopes and accessories.

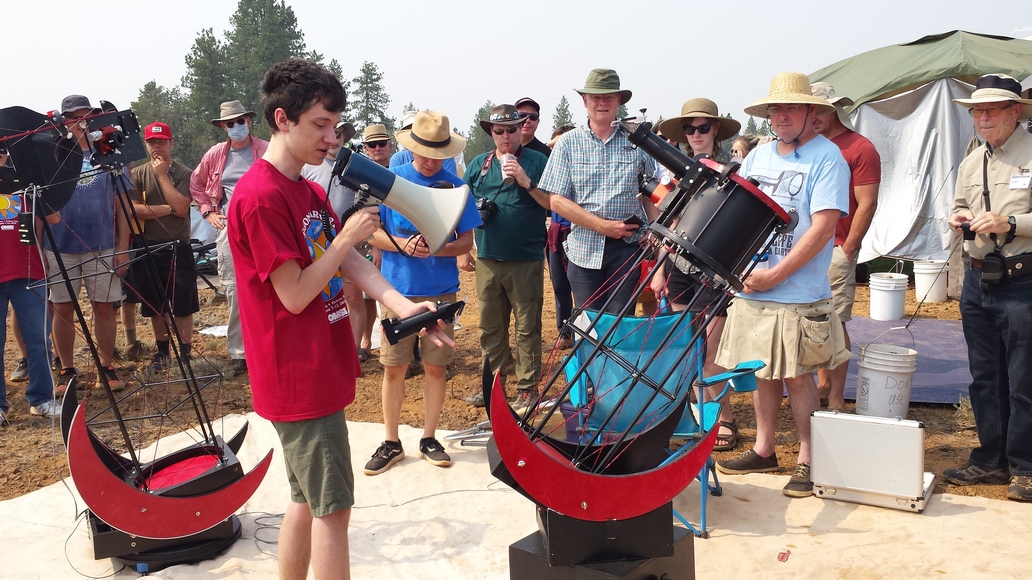

Mel Bartels talking with Howard Banich and Chris Tribe before the Walkabout begins then delivering opening remarks.

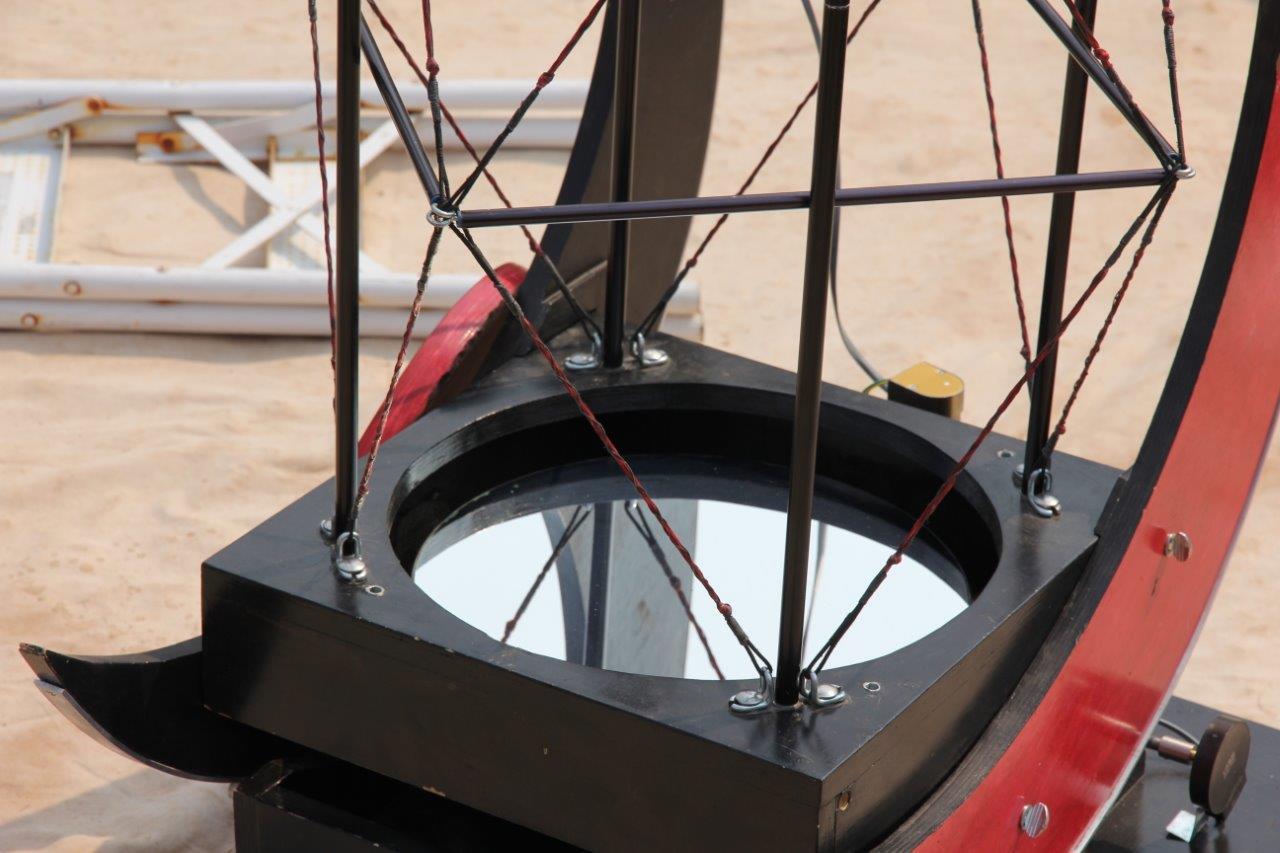

The problem is cranking your head underneath a Telrad and twisting this way and that way to pick up the red circles: it hurts, it is frustrating and it can take time. Quinn's science project was to create a new finder that will 'draw you in' into the pointing circles by using super wide angle circles. An achromatic lens projects the bullseye pattern onto the sky. Quinn also added an on-off switch, missing from the original Telrad, and made sure that the stand-off height was sufficient. The parts are 3D printed and were designed in CAD software. Rob, who is an optical engineer and his son Quinn are considering releasing plans into the public domain and possibly offering parts. Rob's and Quinn's telescopes use a Tensegrity string design - incredibly stiff.

Rob and Howard have been experimenting with silvering mirrors. The cost of aluminizing large amateur mirrors is very high and silver promises better reflectivity. Can silvering deliver? Rob and Howard conducted a lively conversation with the crowd on progress so far and prospects for future improvement. Rob and Howard report that the absolutely critical cleaning process has been perfected, that the silvering is reflective in the upper 90's%, and that current effort is centered on making the silver coating last for at least an observing season if not longer. Pictured is Rob showing his tarnish preventing mirror cover. In the meantime, both Rob and Howard are greatly enjoying their silvered mirror views through the eyepiece.

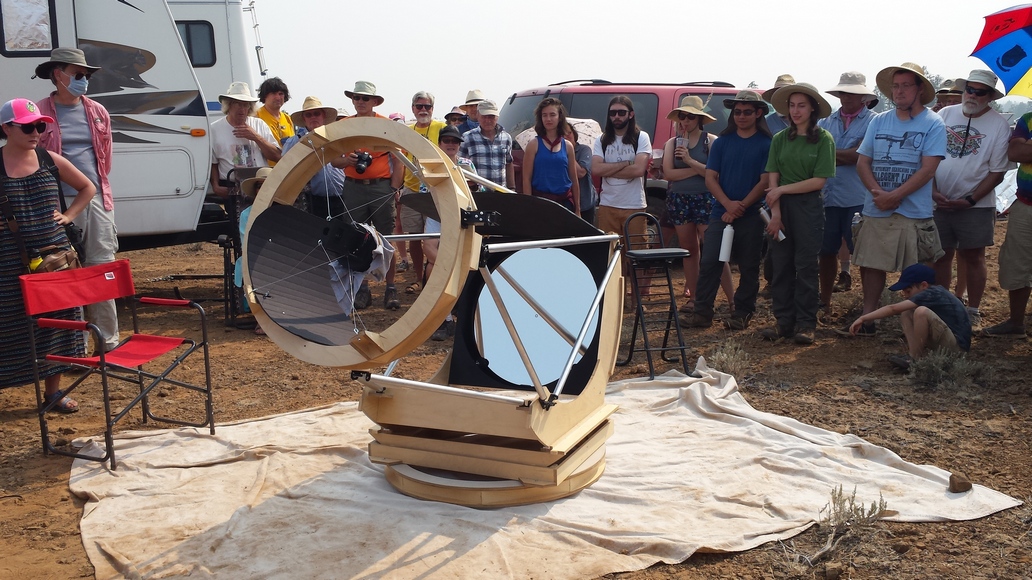

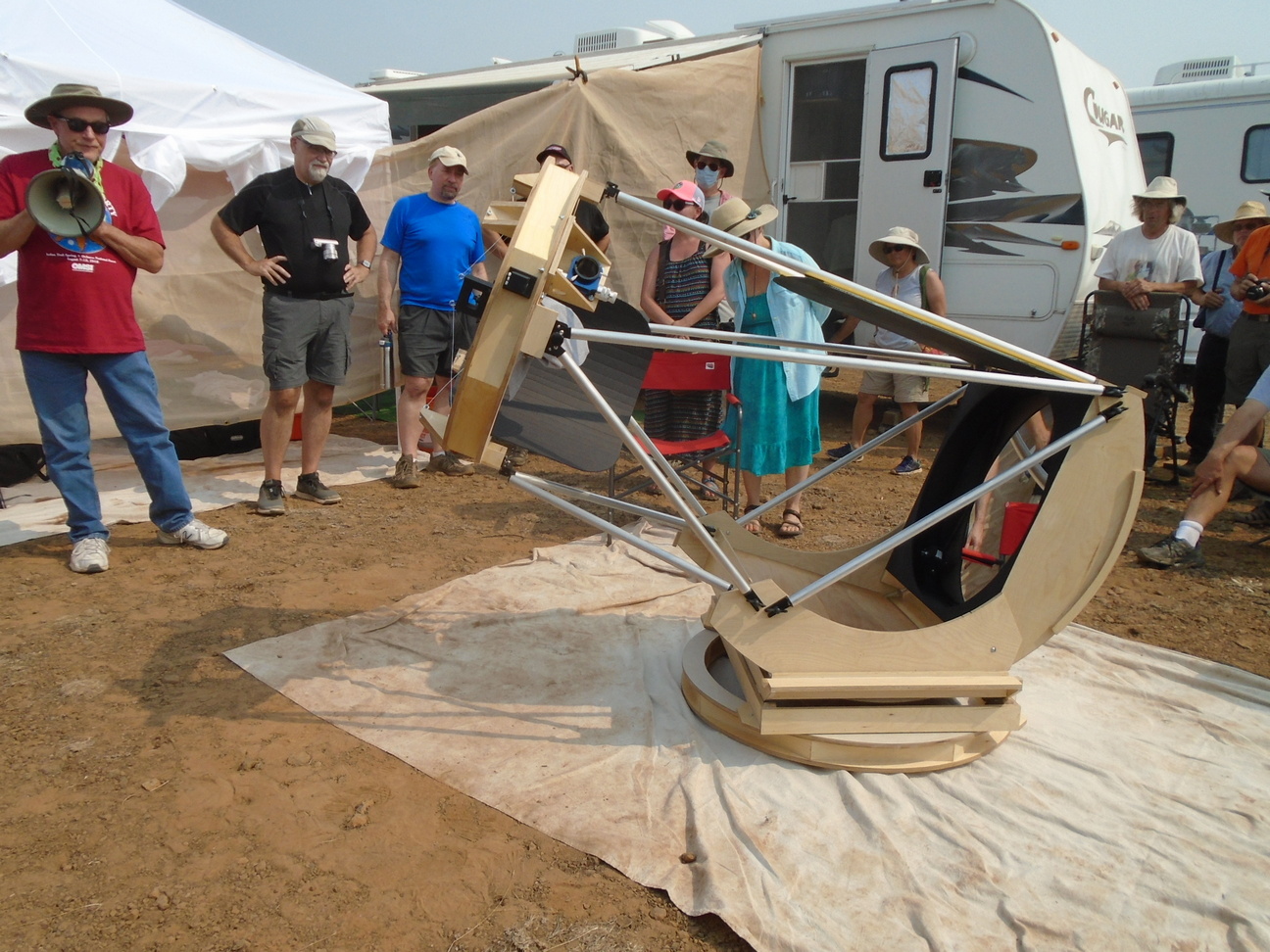

Mel showed his latest creation, a 25 inch f2.6 meniscus mirror that's half an inch thick, residing in a newly invented 3-axis mount. Mel's goal is the largest aperture 'no-ladder' telescope yet still lightweight, with the mirror weighing but 25 pounds and the scope in total weighing 75 pounds. Other features include a wire spider and a fold-up tube assembly design so that the scope will fit through narrow RV doors. The mirror took him two years to make. He reports that he was quite anxious, not knowing if the mirror would work until the initial star test.

Mel has invented a 3-axis mount such that the telescope, when pointed horizontally, moves in the customary altitude and azimuth axes, but when the telescope is pointed vertically at the zenith, the telescope moves in altitude and a secondary altitude axis. The telescope can also point past the zenith. By controlling friction of movement, the telescope transitions between the two motions based on elevation of the telescope. Coupled with 'feet on the ground' viewing, this makes for nice zenith viewing. The third axis can also be used to adjust the eyepiece angle.

More on the telescope.

More on initial observations.

How I made the mirror.

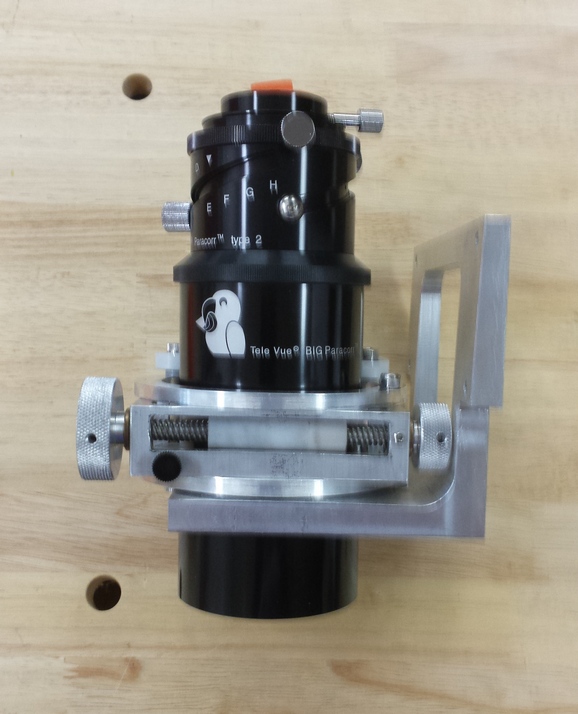

Pierre Lemay has invented a new 3 inch diameter ultra-fine movement helical focuser, building a prototype for Mel's 25 inch. This focuser features an ultra-fine focusing adjustment to go with the coarse twisting-helical adjustment. The idea is to use a 3 inch diameter coma corrector's long body as the focusing tube.

Read his report on Cloudy Nights.

Attendees walking to next stop

Continuing a strong tradition of new binoscopes appearing at the Oregon Star Party (this is binoscope #13 to appear on the Walkabout!). Robert's scope is the future of telescope making with a 3D printed bino-head featuring naturally feeling IPD (InterPupilary Distance) adjustment just like popular handheld binoculars, 2 inch focusers and simplified tertiary and optical alignment adjustments. His focusers include trays for filters. His development process is innovative: 3D print a simple interface to the rest of the scope, then rapidly iterate by designing and refining the part in question, using 3dhubs.com for contract printing work, the typical turnaround being a few days. In effect, his computer workstation becomes his workshop. He likes fusion360 for software and has investigated at length suitable materials to 3D print the parts. His parts also allow for metal parts made elsewhere. The resulting precision is just what a binoscope needs. Binoscopes are the most complex type of telescope to build, calling for extensive machining that might be better dealt with by 3D printing. This is the future of telescope making.

For more, visit Robert's webpages.

eod